Standard Drilling Machine

Ideal for simple and fast drilling.

AEFFE MACHINERY offers to you a wide range of drilling machines in continuous of various sizes (working area): 1800mm, 1600mm, 1200mm, 800mm, 500mm.

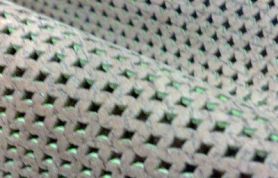

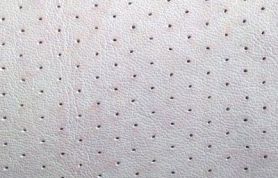

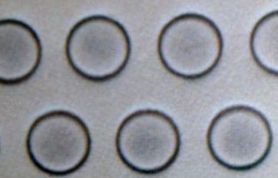

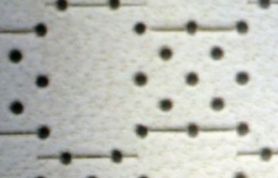

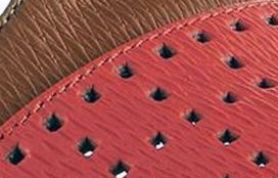

AEFFE’s drilling technology is constantly improved according to the requests and recommendations of our customers. Our standard drilling machines can perform several working processes in continuous, on real leather and synthetic materials: drilling, punching, print, foils transfer by heating, micro-drilling and cuts for weavings. All the models are electronically controlled and the working speed may vary from 0 to 400 strokes per minute.

This kind of machineries can't perform drawing by computer, but items made by standard configuration only. This fact makes them faster, more efficient and more precise than the Factotum models in the specific drilling working process. The paper carpet that carries the materials can be used several times, according to its consumption and proper use during the working processes.

All AEFFE’s machines are in compliance with all existing laws on the subject and then comply to the CE mark.

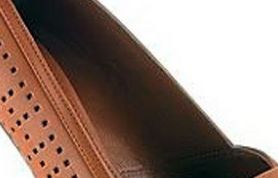

AF 500 / AF 800

AF 500 and AF 800 are the smaller models of notching and drilling machines designed for shoe upper and shoe factories. By their working area of 500 and 800 mm, they are capable of drilling, stamping, plating, engraving for hot and cold, working continuously; of individual parts (uppers) or on rolls of plastic.

The speed is electronically controlled and allows enormous flexibility of speed (0 to 300 strokes per minute). The material is transported by a carpet of paper that is wrapped and held by a motor controlled and can be used multiple times. The machines AF can be mechanical, semiautomatic, automatic and allows the use of molds to "Dies" for the processing of standard materials or molds "Punches" for the materials elastic and spongy.

AF 1200 / AF 1600 / AF 1800

AF 1200, AF 1600 and AF 1800 are the larger drilling and notching machines, they are suitable for machining of tannery and synthetic. By their working areas of 1.200, 1.600 and 1.800 mm, they are capable of drilling, stamping, plating, engraving for hot and cold, and if necessary all at the same time.

These machineries work in continuous on both pieces of whole leathers also work with rolls of synthetic material (the machines have a predisposition for unwinding and winding of the processed material). The powerful motor is electronically controlled and allows a huge change in speed (from 0 to 400 strokes per minute). The carpet of paper that carries the material can be reused several times.

These models can make the standard perforation only and they don’t support the Factotum System.